Send inquiry

Skylights have become an integral feature of contemporary architecture, enhancing indoor spaces by bringing in natural daylight, reducing energy consumption, and creating a sense of openness. Among the wide range of materials used in skylight frames, aluminum alloys, uPVC (unplasticized polyvinyl chloride), and steel are the most common. Each of these materials has distinct properties that affect performance, durability, aesthetics, and cost. Understanding the differences between them can help homeowners, builders, and architects make informed choices. This article explores how aluminum alloy skylights compare to uPVC and steel skylights across key factors such as durability, thermal performance, design flexibility, maintenance, cost, and sustainability.

Durability is often the most important factor when choosing skylight materials, especially because skylights are constantly exposed to sun, rain, wind, and temperature fluctuations.

Aluminum Alloy Skylights

Aluminum alloys are highly resistant to corrosion, rust, and warping. Unlike pure steel, aluminum does not easily oxidize, and with powder coating or anodization, it gains additional protection against harsh weather conditions. This makes aluminum alloy skylights ideal for regions with extreme climates or coastal environments where salt exposure can be damaging. The metal is also lightweight yet strong, offering excellent structural stability without adding excessive load to the roof.

uPVC Skylights

uPVC is non-corrosive and naturally resistant to moisture, which makes it effective in humid environments. However, over time, uPVC can become brittle or discolored when exposed to prolonged UV radiation, even if UV stabilizers are added during manufacturing. While durable for residential use, it generally cannot match the long lifespan of aluminum alloy skylights.

Steel Skylights

Steel is the strongest of the three materials, offering outstanding structural integrity. It is often used in industrial or commercial skylights where large spans require maximum load-bearing capacity. However, untreated steel is highly susceptible to corrosion and must be galvanized or stainless to remain viable in exterior applications. Even then, maintenance against rust is more demanding than aluminum or uPVC.

Verdict: Aluminum alloy skylights strike the best balance between strength, lightness, and resistance to corrosion, while steel provides unmatched strength but requires more maintenance, and uPVC offers adequate durability but is less suited for long-term heavy-duty applications.

One of the primary purposes of skylights is to improve energy efficiency by reducing the need for artificial lighting. However, thermal insulation and heat transfer resistance are equally crucial.

Aluminum Alloy Skylights

Aluminum is a good conductor of heat, which might seem like a disadvantage for insulation. However, modern aluminum skylights are designed with thermal breaks—a non-metallic barrier within the frame that significantly reduces heat transfer. With this technology, aluminum alloy skylights can achieve excellent energy efficiency, especially when paired with double or triple-glazed glass.

uPVC Skylights

uPVC is a natural insulator, which means it inherently resists heat transfer better than aluminum without needing thermal breaks. This makes uPVC skylights effective in maintaining indoor temperature and reducing energy bills. However, because uPVC is less structurally rigid, it may not support very large glass panes without reinforcement, limiting design flexibility.

Steel Skylights

Steel conducts heat even more readily than aluminum and is generally less energy-efficient unless advanced insulating technologies are applied. Additionally, steel frames are prone to thermal bridging, which can cause condensation issues around the skylight.

Verdict: uPVC offers superior natural insulation, but aluminum skylights with thermal breaks now rival or surpass it in performance, especially in premium designs. Steel remains less efficient unless heavily engineered for insulation.

The visual appeal of skylights is an important consideration, especially in modern homes and commercial spaces.

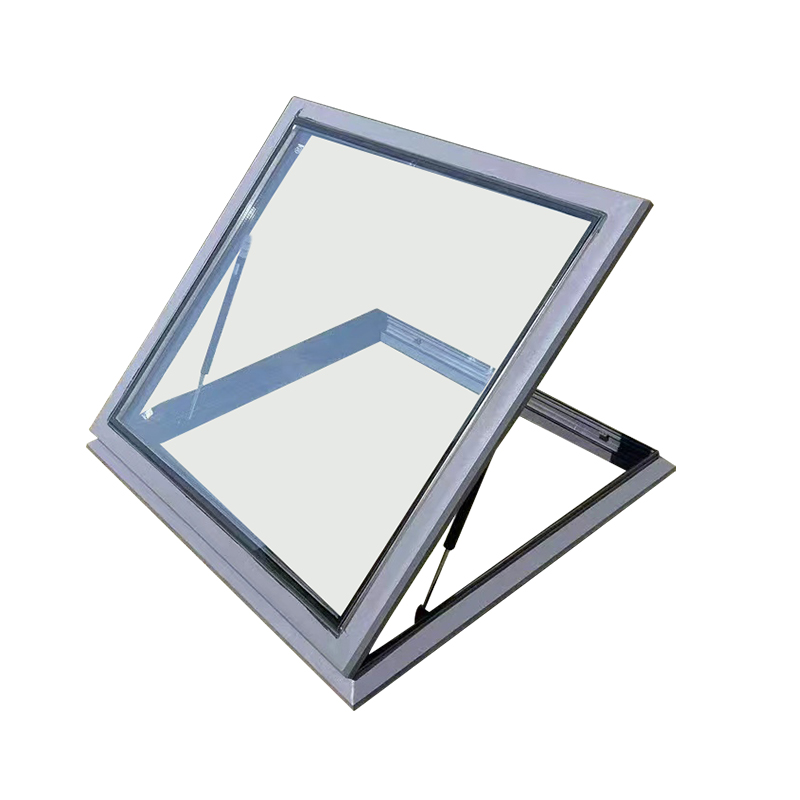

Aluminum Alloy Skylights

Aluminum alloys allow for slim, sleek profiles that maximize the glazed area, letting in more natural light. They can be powder-coated in a wide range of colors and finishes, making them versatile for various architectural styles. Their strength allows for custom shapes, larger spans, and frameless designs, giving architects more creative freedom.

uPVC Skylights

uPVC skylights are typically bulkier because the material requires thicker frames to provide adequate strength. The color range is more limited, often restricted to white or a few laminated finishes, which may not suit all architectural styles. While they offer a clean and simple look, they lack the refined elegance of aluminum.

Steel Skylights

Steel skylights offer a bold, industrial aesthetic that can be appealing in certain modern or commercial designs. Because of steel’s high strength, it can also support large glass areas with thin frames. However, its heavy weight and corrosion concerns sometimes limit its design flexibility.

Verdict: Aluminum skylights offer the most design flexibility and aesthetic appeal, while uPVC is more limited in style options, and steel is best suited for industrial or high-end custom designs.

The lifespan of a skylight depends on both material durability and the maintenance required.

Aluminum Alloy Skylights

With proper coatings, aluminum alloy skylights can last several decades with minimal maintenance. Occasional cleaning and inspection of seals are typically sufficient. Their resistance to rust and warping makes them particularly low-maintenance compared to steel.

uPVC Skylights

uPVC skylights require little maintenance as they do not corrode. However, they may discolor over time, particularly in areas with strong UV exposure. Cleaning is simple, but eventual brittleness may require full replacement after 15–25 years.

Steel Skylights

Steel skylights, unless stainless or heavily treated, demand frequent maintenance to prevent rust. Even with protective coatings, scratches or chips in the finish can expose the metal to corrosion. This increases long-term upkeep costs.

Verdict: Aluminum skylights provide the best combination of longevity and low maintenance. uPVC is nearly maintenance-free but less durable long-term, while steel requires ongoing care.

Cost is often the deciding factor for homeowners and builders.

Aluminum Alloy Skylights

Aluminum skylights fall in the mid-to-high price range. While more expensive than uPVC, they are more affordable than high-grade stainless steel skylights. The investment is justified by their long lifespan, aesthetic versatility, and performance.

uPVC Skylights

uPVC skylights are the most affordable option upfront. This makes them popular for residential projects with tight budgets. However, their shorter lifespan and limited aesthetics may lead to additional replacement costs over time.

Steel Skylights

Steel skylights, especially stainless steel versions, are the most expensive due to material costs and manufacturing complexity. They are often used in specialized commercial projects where strength is prioritized over cost.

Verdict: uPVC wins on initial affordability, aluminum offers the best long-term value, and steel is reserved for high-budget or industrial applications.

With sustainability becoming a growing concern, the environmental impact of skylight materials cannot be ignored.

Aluminum Alloy Skylights

Aluminum is highly recyclable, and recycled aluminum requires only a fraction of the energy used in primary production. This makes aluminum skylights an eco-friendly choice, particularly when paired with energy-efficient glazing.

uPVC Skylights

uPVC production is less eco-friendly due to its reliance on petrochemicals and additives. Recycling options exist but are more limited compared to metals. Additionally, uPVC waste can contribute to environmental concerns.

Steel Skylights

Steel is fully recyclable and has a robust recycling industry, making it sustainable in terms of material reuse. However, the energy intensity of steel production is higher than aluminum, impacting its overall carbon footprint.

Verdict: Aluminum skylights provide the most balanced sustainability benefits, while steel is also recyclable but more resource-intensive, and uPVC is the least eco-friendly option.

When comparing aluminum alloy skylights to uPVC and steel skylights, aluminum emerges as the most versatile and balanced option. It combines strength, durability, aesthetic flexibility, and recyclability with relatively low maintenance requirements. uPVC skylights are a budget-friendly choice with good insulation properties but limited longevity and design options. Steel skylights, while extremely strong and durable, are more expensive and require frequent maintenance, making them best suited for industrial or specialized architectural applications.

For most modern residential and commercial buildings, aluminum alloy skylights provide the optimal balance of performance, aesthetics, and long-term value. With advancements in thermal break technology and sustainable production methods, aluminum continues to set the standard in skylight design and installation.